Introduction:

In recent years, the world of manufacturing has undergone a significant transformation with the emergence of 3D machine printing. This innovative technology has revolutionized the traditional manufacturing processes by enabling the creation of complex and customized objects with unprecedented precision. In this blog post, we will delve into the fascinating world of 3D machine printing, focusing on the revolutionary pbftechnologie additive manufacturing and its impact on the industrial sector.

The Rise of 3D Machine Printing

3D machine printing, also known as additive manufacturing, is a process that involves building three-dimensional objects layer by layer from a digital model. This groundbreaking technology has gained immense popularity due to its versatility and ability to produce intricate geometries that were previously unattainable using conventional manufacturing methods.

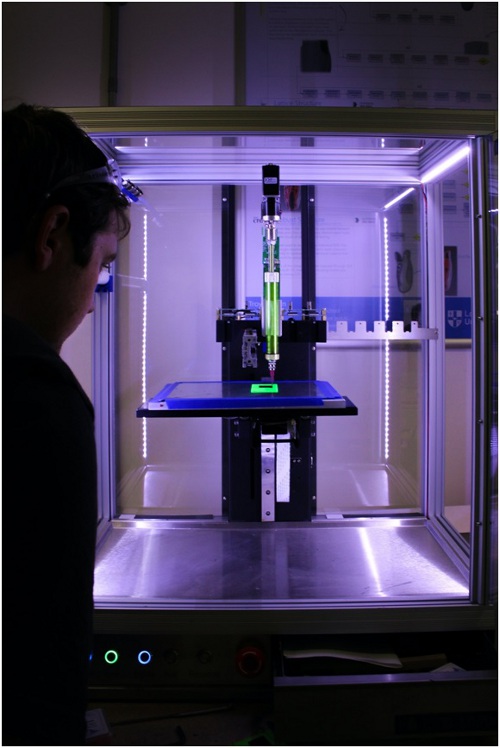

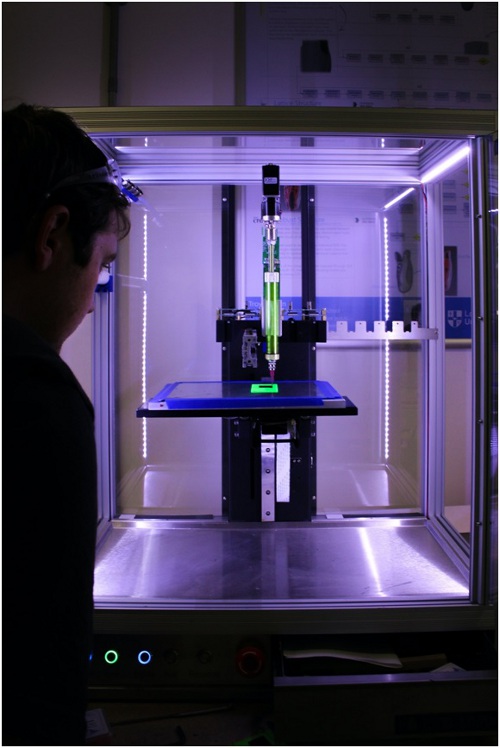

One of the key players in the industrial 3D printing machine manufacturing sector is the pbftechnologie. This leading manufacturer has pioneered the development of advanced 3D printing systems that leverage powder bed fusion (PBF) technology. PBF is a technique where a laser selectively fuses powdered materials, such as metals or polymers, to create complex structures layer by layer.

Advantages of PBF Additive Manufacturing

PBF additive manufacturing offers several advantages over traditional manufacturing techniques, making it an ideal choice for industrial applications. Here are some key benefits:

1. Design Freedom: PBF enables the production of highly intricate designs that were previously unachievable. The layer-by-layer approach allows for the creation of complex internal structures, reducing material waste and maximizing the functionality of the final product.

2. Customization: With PBF additive manufacturing, manufacturers can easily tailor products to meet specific customer requirements. This level of customization enables companies to deliver unique solutions and address individual needs more effectively.

3. Speed and Efficiency: PBF technology has significantly shortened the production cycle by eliminating the need for tooling and reducing assembly requirements. Manufacturers can quickly iterate designs and rapidly bring products to market, resulting in reduced lead times and increased overall efficiency.

4. Cost Savings: Despite the initial investment in 3D printing equipment, PBF additive manufacturing can generate substantial cost savings in the long run. By eliminating the need for complex machining processes and reducing material waste, manufacturers can optimize their production processes and minimize production costs.

Impact on the Industrial Sector

The adoption of PBF additive manufacturing has had a profound impact on the industrial sector. By leveraging the capabilities of 3D machine printing, manufacturers have experienced transformative changes in their production processes. Here are some notable impacts:

1. Supply Chain Optimization: 3D machine printing allows for decentralized manufacturing, reducing the reliance on global supply chains. This technology empowers companies to produce components on-site or closer to the point of use, minimizing lead times and transportation costs.

2. Prototyping and Rapid Iteration: PBF additive manufacturing has revolutionized the prototyping process, enabling manufacturers to quickly iterate designs and test concepts before mass production. This iterative approach enhances product development cycles and fosters innovation.

3. Enhanced Product Performance: The ability to create intricate geometries and lightweight structures through PBF additive manufacturing has led to improved product performance across various industries. From aerospace components to medical implants, 3D machine printing has opened up new possibilities for optimizing functionality and performance.

4. Sustainable Manufacturing: PBF additive manufacturing promotes sustainability by reducing material waste, energy consumption, and harmful emissions. This environmentally friendly approach aligns with the growing emphasis on sustainable practices in the industrial sector.

Conclusion

The advent of 3D machine printing, particularly PBF additive manufacturing, has revolutionized the industrial sector. With its design freedom, customization capabilities, and cost-effective production processes, this technology is reshaping the way manufacturers approach production and product development. As the industrial 3D printing machine manufacturer, pbftechnologie continues to push the boundaries of additive manufacturing, driving innovation and unlocking new possibilities across industries. The future of manufacturing has arrived, and 3D machine printing is leading the way towards a more efficient, sustainable, and dynamic manufacturing landscape.